A boiler is a device that heats water for space heating and hot water. The most common fuel for a boiler is natural gas. But diesel oil, liquid petroleum gas (LPG), electricity, biomass, heat from the air or the ground, and even logs or coal can be used as fuels.

This article covers:

- Finding a registered installer and regulatory requirements when installing a boiler

- Grants available for boiler upgrades

- Pros and cons of heat pumps

- Pros and cons of condensing boilers

- Pros and cons of combi boilers

- Wood burning stoves and furnaces

- Traditional boilers

- Pros and cons of the lesser known electric boilers

- How to upgrade an existing boiler and top maintenance tips

For safety reasons, only registered gas installers and registered electricians can be involved in the installation of gas boilers in your home.

OFTEC is a trade association that sets standards in the world of oil-fired boilers. They manage a ‘competent person’ registration scheme, to help you find installers who really know what they’re doing.

In ROI check the official HARP (Home-heating Appliance Register of Performance) database to compare boilers on a like for like basis.

In NI/the UK, check the NCM/SAP database.

In terms of the regulations, in ROI boilers must have a seasonal efficiency of at least 90 per cent. In NI all new boilers have to be condensing ones, although there are rare exceptions to this rule.

Non-condensing boilers usually take their air from the room but condensing boilers are sealed units that take their air from outside through the flue.

In general the regulations are gradually squeezing out fossil fuels in both NI and ROI as an energy source for newly built homes. Passive homes don’t even need central heating.

For a guide on how to comply with the ROI building regulations for a new build see this Q&A.

Grants

In NI you can avail of a grant to replace your boiler but to be eligible you need to earn less than £40,000, be an owner-occupier and have a boiler that’s at least 15 years old. The allowance doesn’t apply to Economy 7 heating, stoves used only for cooking, back boilers or room heaters. The grant of up to £1,000, dependent on gross annual income, is there to help replace an old, inefficient boiler with a more energy-efficient condensing oil or gas boiler; to switch from oil to gas; to switch to a wood pellet boiler. You must get permission in writing from the Housing Executive before you replace your old boiler.

In ROI the Better Energy Homes grant applies for homes built before 2006, which will fund €3,500 for a heat pump (to be rolled out in April 2018) and €700 towards a heating controls upgrade. You also need to have a Building Energy Rating (BER) carried out before and after the works, but a €50 grant is available to go towards this cost.

More information on grants available in our overview.

Heat pumps

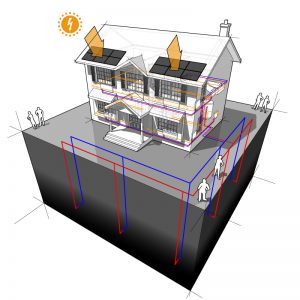

The modern type of ‘boiler’ is the heat pump, an alternative heating source very much becoming the standard on Irish self-build projects as the need for renewable requirements in the ROI Building Regulations squeezes out fossil fuels.

A heat pump is a device that transfers heat energy from a source of heat (soil, air, water) to a destination called a heat sink, working like a fridge in reverse. A heat pump uses a small amount of external power to accomplish this transfer.

The efficiency of any heat pump is maximised when the difference in temperature between the heat source and the heat sink is minimised. Thus, the most efficient systems are suited to low temperature heat distribution networks such as underfloor heating. The lowest efficiency is usually experienced when producing domestic hot water but that depends on the output temperature.

The most tried and tested type of heat pump in Ireland is the groundsource horizontal collector which relies on solar energy to replenish heat in the soil. Moisture movement in the ground is important because it works as a heat transfer agent replacing the cooled water in the collector field.

The area required will depend on the thermal conductivity of the ground and can be significant. Groundworks can set you back quite a bit in terms of cost unless you manage to reduce this by laying the pipes at the same time as you install your septic tank or drainage.

In recent years, the air source heat pump has taken over the market with two main types, one has heat pump component indoors (split) and the other has all parts located in the one unit outdoors (‘monoblock’). Considering Ireland’s mild weather, this plug and play heat pump option has grown in popularity but efficiency starts to drop at lower air temperatures and higher water temperatures. Whilst these units make some noise, and you will have to consider neighbouring properties (as well as its location in relation to your bedroom windows, etc.) don’t locate the unit far from the house as this will reduce efficiency (heat loss in the pipe run). Vertical (borehole) systems are the most expensive but can be the only solution for some sites.

If you have a stream or a lake, an easy, and highly efficient option is laying the pipes as in the horizontal groundsource system but in the water. However gaining planning and environmental consents for these may not be straightforward.

A type of heat pump that’s entering the market in a big way is the exhaust air heat pump, which combines heat recovery ventilation and a heat pump – the hot air generated within the home is used to supply heat and hot water and the house is ventilated in the process. This option is especially useful for apartment upgrades or a small house (200 sqm or less) that is built to very high energy efficiency standards.

All heat pump systems work on the same principles and the component parts are similar; it is the extract methods that differ. Heat pumps can be bolted on to any existing system and there are hybrids which allow the heat pump to be complemented by a fossil fuel boiler (another alternative is to install two heat pumps).

Maintenance will depend on the type of heat pump but get acquainted with your system and check, once a year, that all parts are in order and that the software is up-to-date.

Heat pump pros

- For every unit of electricity you should get a minimum of three units of heat, a ratio referred to as the coefficient of performance. The higher the COP the higher the savings as electricity costs more per unit of energy than fossil fuels.

- Unlike gas, oil, LPG, or biomass heat pumps only run on electricity, an energy source that is becoming cleaner (low carbon emissions) as the renewables share increases in Ireland’s energy mix.

- As there is no fire, there is no need for a flue, chimney, or fuel storage area, making them safe to fit inside or outside.

- Heat pumps can cool in summer, heat in winter and provide hot water all year round.

- No combustion makes them easy to maintain and already there are heat pumps thirty years old working in Ireland.

- A well designed and installed system can increase the value of your home.

- If you already have solar thermal panels in your home, you can integrate the heat pump so the hot water is heated by the solar collectors first, increasing efficiency.

- Deluxe models allow the heat pump to automatically switch between heating and hot water with weather controls.

- The planners like them and they tick the renewables requirements of the ROI Building Regulations.

- Some heat pumps can produce 65 degC flow temperature suitable for heating radiators in older buildings.

- Off-grid living is made possible with photovoltaic (PV) panels and battery storage, but do choose a heat pump with Smart Grid that monitors the PV output and household use to optimise efficiency.

Heat pump cons

- Poor quality cheap heat pumps can work out more expensive than oil or gas to run and have a short operating life, between five and ten years. Often used on build-to-sell properties.

- Expensive to buy and install when compared with a standard boiler. This means, in effect, that most people who can use another system usually do, missing the opportunity on investing to save.

- Contributing to the expense is the cost of the hot water tank; to get the best out of any heat pump system you generally need an 800 litre capacity tank (at a cost of around £/€1/litre) which also takes up considerable space.

- When installing a heat pump into an old building to replace oil you need to carry out an energy upgrade to get the best results – insulation, airtightness and ventilation standards – which further increases capital costs.

- The refrigerant gas used in the heat pump must be ‘green’, which comes as standard in heat pumps that comply with European standards but carefully check other provenances.

- New regulations require heat load calculations be done by an expert as system sizing is the key to a successful installation.

- The nature of the installation is also more complex and few installers have the required experience compared to fitting oil or gas boilers. This means it is more important to rely on the manufacturer’s recommendations rather than the installer’s to secure a good result.

Condensing Boilers

These are usually fuelled by gas or oil and make more efficient use of the fuel they burn than do non-condensing boilers. The technology behind them means that they achieve better than 90 per cent efficiency by also condensing the water vapour in the exhaust gases, so recovering the latent heat of vaporisation that would otherwise be lost to the outside air. Most modern non-condensing boilers are only about 80 to 90 per cent efficient because so much heat is lost in their outflow gases. This heat is largely recovered by a condensing boiler when a low return flow temperature is maintained.

Condensing boilers went through a period of being seen as less reliable than standard boilers but they are as reliable as a standard boiler, no more difficult or expensive to service, not difficult to install, and always substantially more efficient than standard boilers.

Unfortunately, condensing boilers are more expensive to buy because they are more complex in design, manufacture and function.

The European ErP rating assigns efficiency ratings from A+++ to G and is displayed on a label on your boiler.

Combi Boilers

A combination or ‘combi’ boiler combines a highly efficient water heater and a central heating boiler in one small unit. It takes cold water direct from the mains when you turn on a tap, passes it through a heater and supplies hot water. Though oil and electric combis are available, the vast majority are fuelled by gas or LPG.

People often get confused when buying a combi boiler, thinking that if they get one that has a large heating power (lots of kW) they’ll have a better system. This isn’t the case. The quoted ‘flow rates’ for combi boilers are determined solely by the flow rate of your incoming mains water. Obviously a boiler with a higher kW rating will heat the water faster but this will not increase the flow rate to your taps. On one job I did, my first task was to put in a new (larger) incoming mains feed to the home, to enable a good flow rate of hot water from the combi.

Combi boilers con

- Because they heat and deliver water at once, you won’t need a hot water storage tank. This is good because it means that you won’t have to buy one, find space for it, or lose heat from it while the hot water is stored awaiting use.

- Because a combi boiler delivers water at mains pressure, provided your pressure and flow rate are good and the system is well designed, water coming out of your taps will all be pressurised, so you won’t need pumps etc for showers.

- Because combis are very compact they are great for small properties and flats.

- Because there is no need for a cold water storage tank to ‘feed’ the boiler, it frees up your loft for conversion and also avoids any freezing-up issues in the winter as your loft gets cold around your cold water tank.

- They are more efficient than older-style boilers.

- They can be cheaper to install as the plumbing required is often simpler than for a conventional boiler with its associated tanks, pipework etc.

- They are good for the impatient….hot water comes out of the tap predictably and rapidly! This is good if you lead a busy life that means you sometimes forget to ensure your hot water cylinder is full when you need it.

- Can be a good point when you sell your home (as the boiler’s details will show on your home’s energy rating – BER/EPC).

Combi boilers cons

- You must have good mains-water flow and pressure to your home. Without this, you can’t have a combi boiler.

- It’s not necessarily the best system if you need to be running several taps at the same time.

- If it’s also used to heat water, be aware the boiler can only produce so much at one time. This is limited by the number of kW of heat it can produce and the flow of water available to it from the mains supply.

- As there is no hot water cylinder you can’t have a back-up immersion heater. This leaves you vulnerable should your combi boiler break down.

- You can’t have a power shower with a combi because water pressure is set by the mains supply coming into the house.

Traditional boilers

Also known as ‘heat-only’ boilers, traditional boilers are best for homes that already have an existing, traditional, heating system linked to a hot-water cylinder. Such a boiler needs a cold-water storage tank in the loft to feed the hot-water cylinder and another tank that maintains the water level in the central heating system.

Traditional boilers pros

Good for replacing a boiler in an old system that might be incapable of dealing with the high pressures delivered by certain combi or system boilers.

Ideal where there’s a big demand for hot water at any one moment.

Can be used effectively in combination with other forms of heat (solar, etc.)

Traditional boilers cons

The tanks required in the loft can restrict what you can do with your loft space.

Because a larger home with several bathrooms will need lots of hot water, you’ll need space to install a large cylinder.

System boilers, meanwhile, need a cylinder (hot water tank) for storing hot water but don’t need a tank in the loft. These are good for homes with more than one bath or shower room, where the demand for hot water at any one time can be high. Most of the main components are built into the boiler, making it easier and quicker to install than traditional boilers.

Wood-burning stoves and furnaces

It’s possible to install a wood-burning stove that doesn’t just heat your room but also your hot water. Depending on the size it can also run several radiators. Such stoves don’t rely on electricity to circulate their hot water but usually require a pump to run radiators, so are good if you have an unreliable hot water supply. If you decide to install a wood-burning boiler you may need a thermal store which can store the excess heat as hot water for taps and space heating.

Furnaces that use wood pellets are becoming more popular today. The beauty of these boilers is that they can run totally automatically, feeding themselves from a hopper of wood pellets, controlled like you would an ordinary oil or gas boiler although they do require regular cleaning and ash disposal. The only real downside is that you’ll need a lot of space to store a large volume of pellets. This means, in effect, being able to accommodate three tonnes (about 80 per cent of a typical house’s annual needs) in a clean, dry place that has been approved by your local building and fire regulation officers.

Electric boilers

Many people don’t realise that electric boilers exist but they can be a life-saver if you are off the gas grid and have no space to store oil or other fuels. This makes them ideal for flats and small homes. Such boilers can produce both hot water and space heating but aren’t suitable for large homes because they can’t supply enough heat.

Electric boiler pros

- They are small and can be tucked away almost anywhere. This makes them ideal for small rental properties.

- They are silent in operation. Because they have almost no moving parts and don’t burn anything you don’t hear them firing up, or indeed, working at all.

- Compared with any other sort of boiler they are cheap to install and easy to maintain.

- They are safe because nothing burns, there are no fumes and you don’t need a flue.

- They can be linked to solar panels or other sustainable heat source, so saving on electricity.

- They don’t need to be regularly inspected and certified each year… another feature that makes them attractive to landlords.

- They can be programmed to use off-peak electricity, storing hot water in a separate tank for when you need it.

Electric boilers cons

- They are limited in how much heat they can produce at any one time.

- They still need a hot-water storage tank.

- They are not nearly as efficient (‘green’) as heat pumps, as they use electricity on a one-for-one basis. That is, you only get out what you put in. This, in turn, means that they are often more expensive to run than oil or gas boilers as electricity is the most expensive energy source.

Existing boilers

Whatever type of boiler you currently have, if it’s more than 15 years old there’s often a good case for replacing it, as the efficiency of new boilers is dramatically better; they are very much ‘greener’; and running costs are generally substantially lower.

But before you replace an old boiler with a new one, take advice about flushing out your existing system. Over time, oxygen in your heating system’s water reacts with the metals of the pipes, radiators and working parts of the boiler to produce sludge which starts to clog up your pipework and, indeed, the whole system.

So be certain that all this material has been thoroughly flushed out and a rust inhibitor put into the system. Be aware, though, that caution should be exercised on older systems as power flushing can expose leaks that may not have been evident in normal operation.

Top 10 Maintenance tips

Although you should have your boiler professionally serviced each year there are lots of things you can do yourself to ensure the efficient and safe running of your system between professional services.

- Check your boiler regularly for any signs of leaks.

- Make sure your boiler’s condensate pipe is properly lagged so it doesn’t freeze in winter.

- Run your central heating two or three times over the summer months, to keep the pumps from seizing up.

- Bleed your radiators regularly to remove air from the system.

- Look for any sooty, black marks around your boiler and if you see any, call for professional help at once.

- Keep a careful eye on your boiler’s air supply….don’t restrict it by piling things around the boiler or blocking up vents. Make sure there is a good air supply at all times.

- Check that your external flues are all free from blockages.

- If you have an oil boiler, be certain to check the oil level in your tank frequently. If you run out of oil, debris and gunge can be sucked into the boiler, causing expensive problems.

- If your boiler is in a room, be sure to have a working carbon monoxide monitor installed in that room. Check once a month that it works.

- If you can see your pilot light, check that it is blue and strong. If the flame is yellow or smoky, get professional help at once.

Note: The scope of this article does not cover dry heating systems, i.e. systems that do not rely on water.